Exactly, what are Bucket Elevators ?

Nowadays, as the world is getting modernised and mechanical, the use of machines have increased. Bucket Elevator is one of the most popular machine, used to transfer materials vertically.

A Bucket Elevator or a grain leg, is a machine, that consists of buckets, which are attached on to a specific type of belt or chain to carry the buckets or may say specific load and transmit the pull machine to drive the belt and accessories, vertically.

Uses of Bucket Elevators

It is mainly used in oil mills,rice industries,grain industries,coal handling,cement industries etc. It is very important accessory of any industries, as it can convey light to heavy materials with ease, without any interruption.The Bucket Elevators,are serving well and getting popular due to simplicity of bucket elevator systems. They are one of the popular choice for handling bulk materials and in processing applications.

Design of Bucket Elevators

Design of bucket elevators depends of types of materials convey,materials transfer capacity and operating specifications.as per design requirements we select sizes of buckets, head and boot profiles, motor and gear box.

Types of Bucket Elevators

Centrifugal Discharge Elevator

centrifugal discharge bucket elevator

Many types of bucket elevators are used as per requirement, The most

common elevator is Centrifugal Discharge Elevator, which may be vertical

or inclined.The vertical elevators is driven by centrifugal force,

which, put the oil into the discharge chute and help run at a relatively

high speed.On Inclined elevators, the buckets are bolted on belt or

chain at perticular pitch , having the discharge chute set partly under

the head pulley.inclined elevator speed is low because it doesn’t depend

on the centrifugal force.On Centrifugal Elevator, the material loaded

from a boot, a pit or a pile.buckets bolted on to the belt, with little

or no space in between them, are being used to carry heavy material,

lifting at a slow pace.Earlier steel buckets are used,now new plastic

bucket with rubber belts, due to convenience and ease to use it.Further,

the pulleys are being used at the top and bottom and driven by an

electric power.

Various types of chains or belts as traction element, different bucket

of different shapes and sizes are applied to make the bulk material

handling possible and easy.

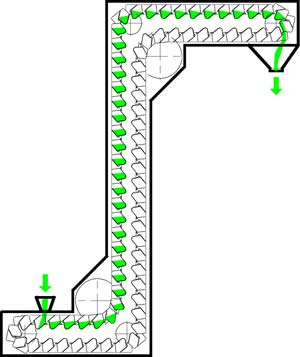

The Continuous Bucket Elevator can be conveyed

horizontal-vertical-horizontal, smoothly and continuously from one or

multiple feed point(s) and then move horizontally to the discharge

point. continuous Bucket Elevators are designed to handle products

without material deterioration move undisturbed until it is discharged.

Advantages of Bucket Elevators

Neo Bucket Elevators provide various advantages economically.

Preferred in various industries

Huge bulk conveying

Easily reach heights

Uninterrupted transportation of material

Smooth and steady functioning

Wide range

Serves for long period

Low driving power

Less or maintenance free

Most trusted machine

Economical and effective

Less labour cost

Comments

Post a Comment